Rego Development is the right partner for projects pertaining to parts manufactured using thermoplastics or silicone rubber.

We have access to full featured design tools with mold flow simulation, advising solutions for integrations of electrical circuits, software for product and an extensive network.

One of our core competences is designing for multi component moulding, including 2-shot Plastic-Silicone parts. There are many factors to keep in account when designing 2-C silicone parts. Let us be your advisor in the early stage to ensure a successful project.

Rego Development can help you to select and execute the right prototyping technologies for exactly your demands and needs.

We have access to all commonly used prototyping technologies, including additive manufacturing, CNC machining and prototype moulding.

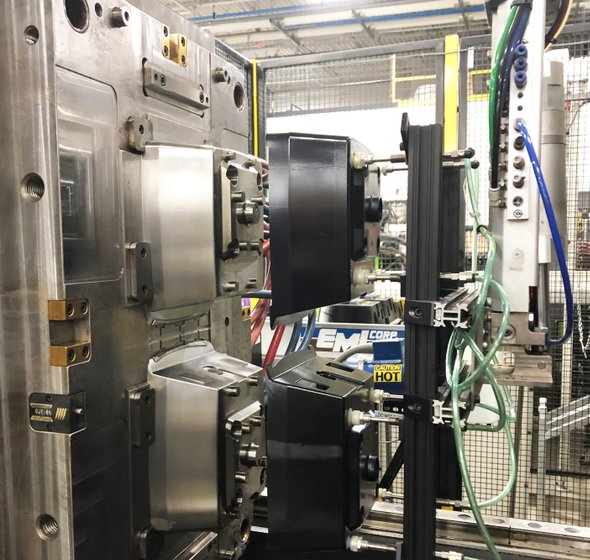

Full scale production capabilities

Rego Silicones Group can offer solutions for mass producing your product.

The production capabilities that we offer includes: Injection Moulding in ISO13485 certified Medical environment, ISO9001 Certified Silicone Injection Moulding, silicone extrusion in both Medical and Technical

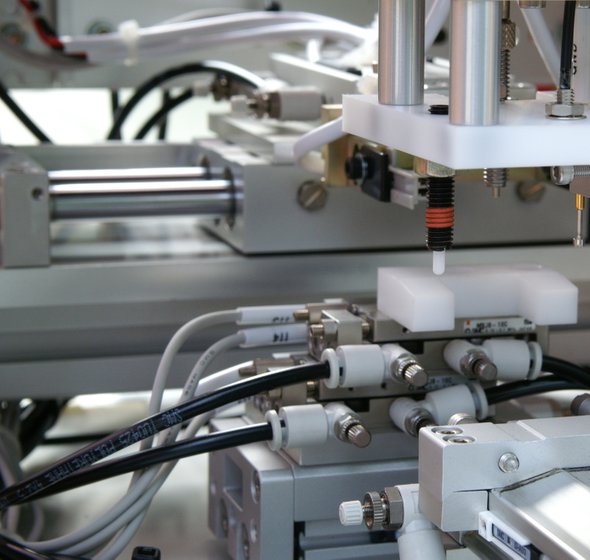

Let us design the special tooling and test equipment for your product.

We can supply test rigs for testing mechanical and electrical properties for tour product.

Rego development has access to a fully equipped CNC tool shop for the manufacturing of your special tools and fixtures.

Contact Rego Development and let us convince you that we are the right partner for your next development project.